Description

Nickel chrome resistance wires

With high and stable resistance, corrosion resistance, surface oxidation resistance is good, a better under high temperature and seismic strength, good ductility, good workability and weldability, it is widely used in industrial electric furnace, metallurgy, household appliances, machinery manufacturing, heating element and resistor varistor other material.

NiCr80 is an alloy with 80% nickel and 20% chromium, which represents the highest standard in materials that can be used in high temperature environments. It can be used at temperatures up to 1200 °

NiCr70 contains 70% nickel and 30% chromium, iron for the remaining percentage and can be used up to 1250 ° C.

NiCr60 contains 60% nickel and 15% chromium, iron for the remaining percentage and can be used up to 1150 ° C. It is the reference material, widely accepted and used for electric heating.

Other Name: Chromel A, Nikrothal 80, N8, Nichrome V, Tophet A,Cronix 80, Alloy A, MWS-650, Stablohm 650; Chromel C, Nikrothal 60, N6, Tophet C, Cronifer II, Nichrome Alloy C, MWS-675, Stablohm 675;

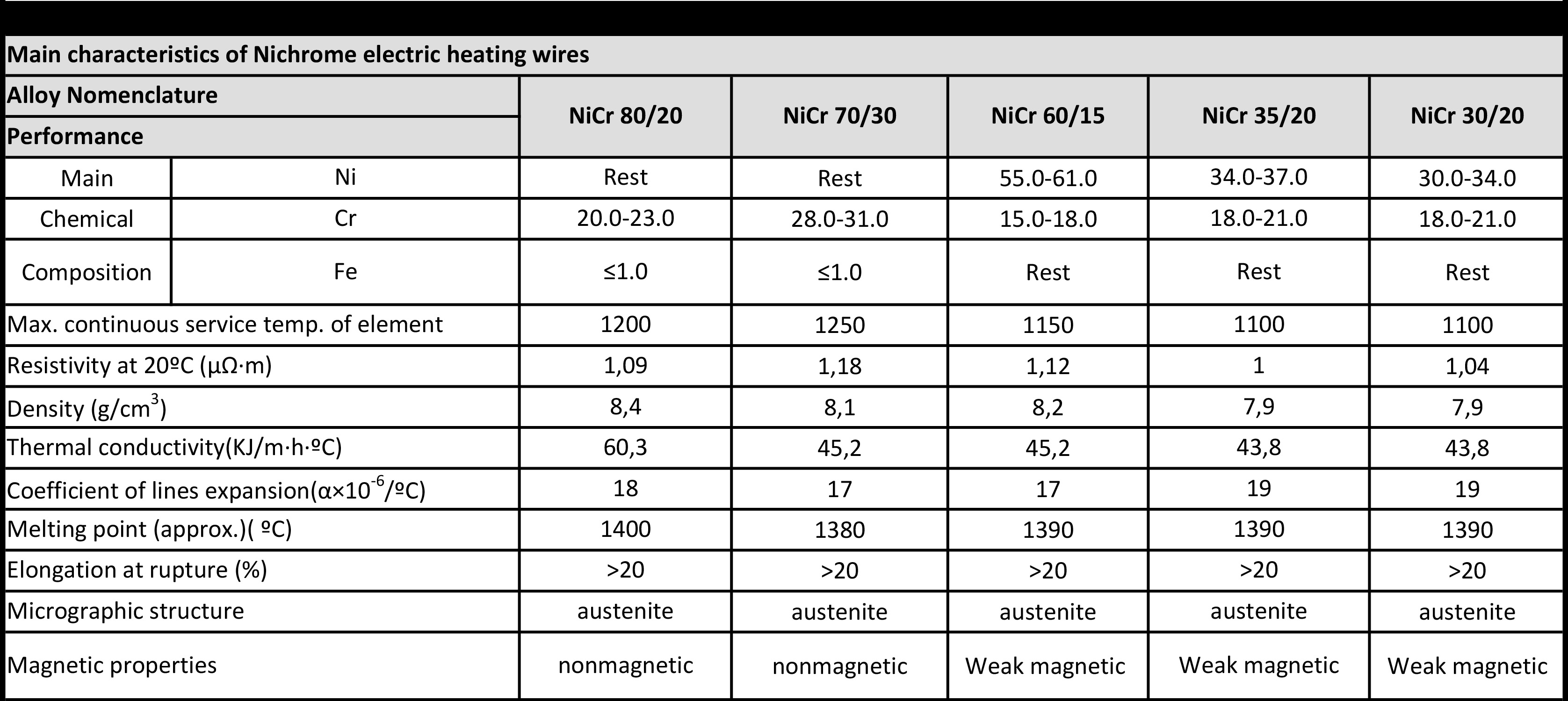

Main characteristics of Nichrome electric heating alloys

BOBINE DIN 125 | DIN 160 | DIN 200 | DIN 250 | DIN 355 |

MATASSE 25 – 50 – 100 -250 KG

DATA SHEET